含硫纤维素衍生物的制备及性能研究

摘要含硫纤维素主要有巯基纤维素(SC)、纤维素磺原酸酯(CCX)和聚硫醚型纤维素(PTCC)三种衍生物。这些含硫纤维素衍生物作为功能高分子材料,主要应用于分析化学、环境科学与工程、化学化工、冶金等领域。本论文对这三种含硫纤维素衍生物的制备、材料性能、吸附性能、解吸再生性能、吸附机理及其应用进行了系统性研究。SC的制备方法:棉花先经过冰醋酸润胀,然后按15g棉花-100mL巯基乙酸-浓硫酸1.0mL的比例,在40°C条件下,反应48小时。制备的巯基纤维素色泽洁白、机械强度较好,碘量法测定巯基含量在1.70%左右。CCX的制备方法:将脱脂棉撕成小片,在常温下浸入10%~20%的NaOH溶液中制备碱...

相关推荐

-

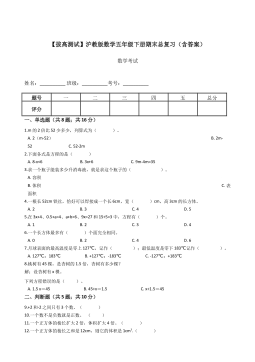

【拔高测试】沪教版数学五年级下册期末总复习(含答案)VIP免费

2024-11-19 19

2024-11-19 19 -

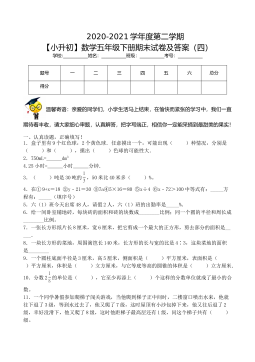

【基础卷】小学数学五年级下册期末小升初试卷四(沪教版,含答案)VIP免费

2024-11-19 9

2024-11-19 9 -

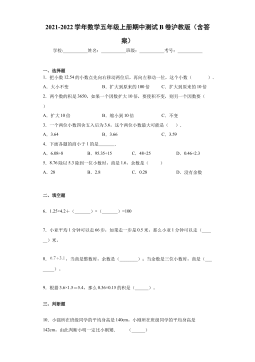

期中测试B卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 11

2024-11-19 11 -

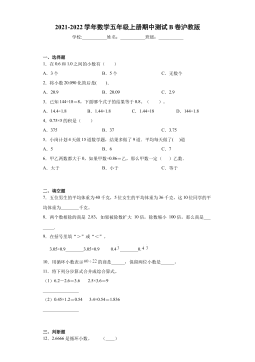

期中测试B卷(试题)- 2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 16

2024-11-19 16 -

期中测试A卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 18

2024-11-19 18 -

期中测试A卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 25

2024-11-19 25 -

期中测B试卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 23

2024-11-19 23 -

期中测A试卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 31

2024-11-19 31 -

【七大类型简便计算狂刷题】四下数学+答案

2025-03-18 16

2025-03-18 16 -

【课内金句仿写每日一练】四下语文

2025-03-18 39

2025-03-18 39

相关内容

-

期中测试A卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

期中测B试卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

期中测A试卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

【七大类型简便计算狂刷题】四下数学+答案

分类:中小学教育资料

时间:2025-03-18

标签:数学计算;校内数学

格式:PDF

价格:1 积分

-

【课内金句仿写每日一练】四下语文

分类:中小学教育资料

时间:2025-03-18

标签:无

格式:PDF

价格:1 积分